Force Sensor

Force Sensor

Load Cell

Load Cell

Torque Force Sensor

Torque Force Sensor

Multi-axis Force Sensor

Multi-axis Force Sensor

Piezoelectric Force Sensor

Piezoelectric Force Sensor

Pancake load cell is also known as low profile load cell, because it has a low-profile design and it looks like a pancake. On the other hand, pancake load cell can bear both tension and compression force. So it is also a tension and compression load cell that is widely used for platform scale, truck scale, rail weighbridge and tension tester.

1. Structure of pancake load cell

To learn more about a pancake load cell, we will analyze the structure of the pancake load cell first.

As we know that the strain gauge load cell is mainly composed of three parts: strain gauge, elastic element and measuring circuit. Among them, the basic principle of the measuring circuit of the load cell is the same, and the strain gauge with small volume will not have a large influence on the structure of the load cell. The reason for there are so many types of load cells is that the load cell manufacturer has been retrofitting and designing a more reasonable mechanical structure according to the application of the load cell, and thus designing various elastic elements of different shapes, so the load cell has more and more shapes. Meanwhile, users are getting simpler when using and installing load cells.

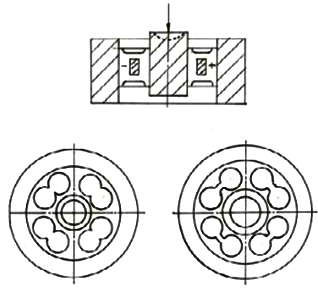

The elastic element of pancake load cell is a hole-structured elastic element. Its whole structure looks like a wheel, and multiple mutually symmetrically distributed spokes have been formed between hubs and tires. The external load is exerted on the upper end face of the wheel hub. The hub, spoke and tire jointly constitute multiple shear beams with fixed supporting on two sides. The hole-structured elastic element is shown as follows.

The hole-structured shear stress elastic elements have a low appearance and good stability. It is not sensitive to the bending moment and has good linearity. The transverse stiffness is large, and the resistance against lateral and eccentric load is strong. The integrated structure is symmetric, and the thermal expansion in different directions is consistent with each other. The temperature coefficient is small.

The hole-structured elastic element adopts the simple drilling process. To ensure that the cross-sectional shear beam has a large stiffness at the root part and a small stress concentration, the strain area is at the pure-shear stress state, which can make the pasting position of the resistance strain gauge more reasonable. If there are many holes formed for the shear strain beams, it will be easier to obtain an ideal stress field which is suitable to paste the resistance strain gauge.

2. Advantage and disadvantage of pancake load cell

According to the above, we can know the advantage and disadvantage of the pancake load cell.

However, when selecting a load cell, we should pay more attention to the installation conditions of the load cell under the same parameters of accuracy and capacity. Below we will compare pancake load cell with other load cells to determine whether to choose a pancake load cell or not.

3. Pancake load cell vs. s type load cell

4. Pancake load cell vs. column type load cell